An overview on key benefits you get with stainless steel products

Stainless steel tube, which is often used in solid-based applications to specifically convey water and other liquids, has come a long way since the first studies. More than a century ago, French scientists conducted substantial studies on the production of stainless steel and metal plate. Today, science has advanced to the point where many special stainless-steel alloys are being developed for several special applications.

Suitable for a range of applications

The metal has several desirable properties, especially with regard to the retention of clear water, and is suitable for a wider range of applications. Stainless steel pipe can also be used to provide structural support in cars and structures. The Steel Supplier Singapore provide extensive quality of the products. Pipes are often made in very specific and appropriate sizes and dimensions. The only difference between a Stainless Steel Singapore tube and a tube is the amount of technology invested in its manufacture, with the tube essentially having a well-calibrated engineering quality. The twin tube suppliers were very good.

Dimensions and performance of a pipe

There are specifically three basic processes for making pipes used by Aluminium Supplier Singapore, which allow a wide range of shapes, sizes and quality. The pipes can be made in square, triangular or polygonal shapes, in addition to the usual cylindrical shape. To meet certain standards, the pipe can undergo additional machining and be made with special alloys to withstand certain stresses. You can find many flange suppliers of duplex tubes.

Stainless steel tube

Specifically, there are two types of tubes, one of which is seamless. Extrusion appears to be the process by which stainless steel twin screws are forced through a specific die along the desired tubular shape. This type of pipe can be made using hot or cold techniques. This strategy is effective and efficient, although it requires a great deal of planning.

Drawn or welded with Mandrel

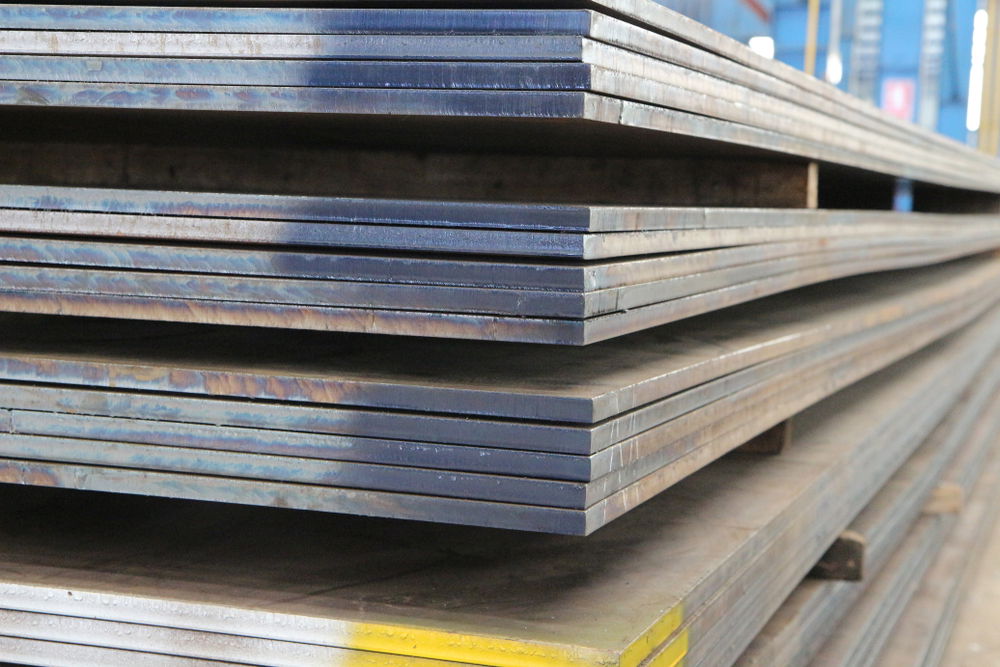

Welding is actually a second method of producing tube. Stretched steel plates are passed around the frame through welding rollers with grooves. A fine line seam or purlin is welded by sending electricity to specific contact points along the seam. Another way to make tubes is to always insert a small metal device called a mandrel into the tube to define its shape. The tube shrinks to conform to the shape of the door as it moves through a head with a much smaller diameter. The double bolt 2205 is excellent.

Applications in Various Industries

Due to its adaptability, excellent corrosion resistance and relatively low maintenance cost, L7 stainless steel bolts are widely used. There are several grades of stainless steel and the variety of pipe applications varies from industry to industry. A wide range of pipes are used in the domestic, architectural, civil, transport, chemical, pharmaceutical, petroleum and water treatment sectors, including stainless steel heating pipes, precision pipes and special steel pipes.

General

The manufacture of and above Inconel 625 commercial stainless steel tubing is highly advanced and increasingly technological. This activity currently requires the highest degree of skill. This company presents a definite vision for the future and supports the success of a diverse group of companies globally serving the specialty petrochemical industry, oil refineries, innovative developments in automobiles, precision instruments and other very special requirements.